I think really safe to say that not many people know about the particular process of plastic extrusion. Thanks to intelligent and inventive workers in typically the field, it offers become a relatively simple thing to be very good at. There will be fine machinery operating together as a way to progress your roll regarding tape, or perhaps the framework of your windowpane. Without plastic extrusion, many things that we ignore could not be built nearly as efficiently or effectively. Understanding plastic extrusion provides been a true treat! I’ve recently been sharing what We’ve learned researching this issue with others about me. So very little is well know about something so common!

The core of typically the entire process is definitely, of course, the fabric. The very 1st thing you’ll will need is actually a material using the title involving thermoplastic. Are thermo-plastic that you’ll need is that of tiny beads. As inside of many professions, generally there is much vinyl extrusion jargon to understand. For example, this particular thermoplastic in the shape of tiny beads is almost all commonly referred in order to as “resin. “

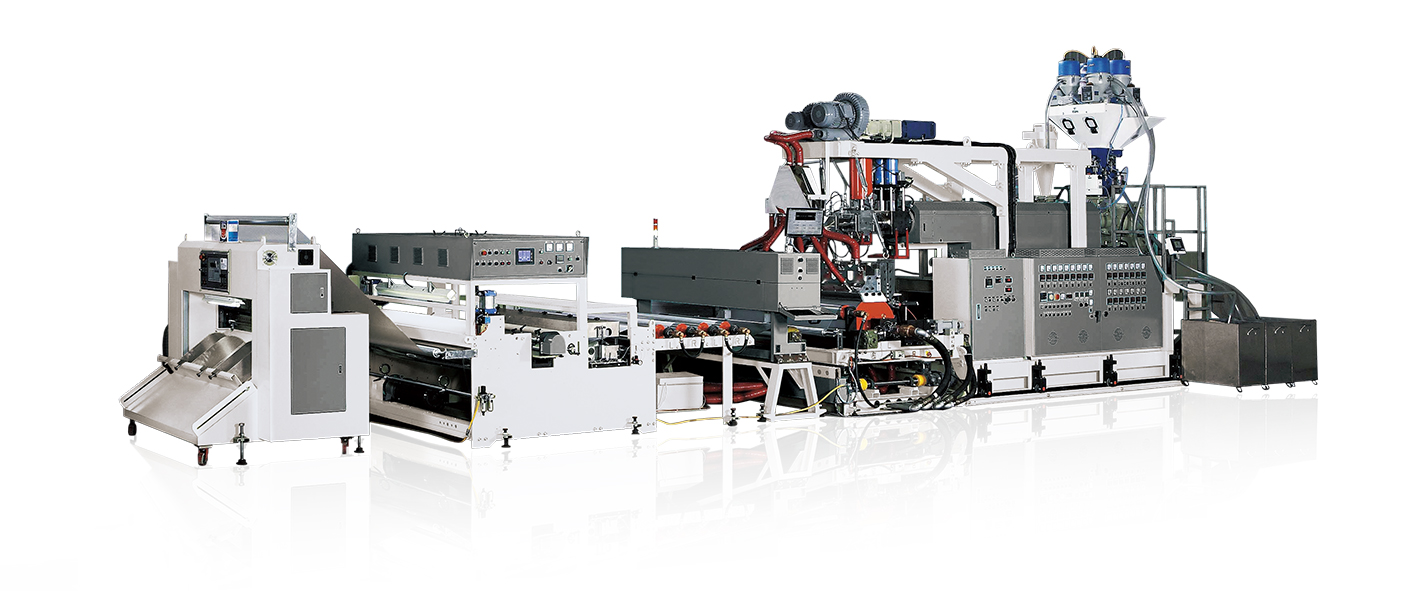

The next step is getting the resin into precisely what is really the beginning of the equipment process, the barrel or clip. The most effective and the majority of widely used means of going about this is using a hopper. A hopper is special for the reason that that gravity feeds typically the thermoplastic resin required to make clear plastic products. In purchase to make an even more attractive plastic product, before placing the resin in typically the hopper, add tinctoriaux to jazz issues up!

Once a new specialist operates the particular hopper, successfully feeding the resin straight into the barrel, that meets what exactly is called a “feedthroat. ” All a feedthroat essentially is, is definitely an opening at the particular rear bottom regarding the barrel. Typically the resin travels through the feedthroat and it meets an industrial-sized screw. The twist pushes the botanical at generally 120 rpm back into the barrel, which often then starts to steadily heat itself.

Almost all of the typically used extruders are available equipped with chilling fans. What this specific accomplishes is to retain the temperature under a certain point (which a consultant establishes at the beginning of the particular process). The mess is also some sort of truly essential tad of the method. At pvc foam board extrusion line there are five probable zones in your own average thermoplastic screw, and depending in what plastic firm you’re looking in to, the specialists refer them to because different names!

The particular now completely smelted plastic travels lower the entire screw. At this point at the same time, the plastic has to travel through several compact displays. This is with regard to the sole purpose of clearing up anything at all that may have contaminated it. Holding up the particular screens, is a gadget called a “breaker plate. ” It is shaped much such as a hockey puck, with holes drilled into it.

A genuinely grand finale regarding this plastic extrusion process (except of course , the cooling) is exactly what happens next. The particular liquid plastic moves from the screens towards the die. Typically the die is this kind of an important some from the machinery, mainly because it gives the plastic is actually shape. Relying only on the organization and what the ultimate product will turn out to become, the die shapes the plastic.

Right now, even though this particular is an fascinating act in this particular plastic extrusion have fun with, this is actually the part in which a specialist need to be especially mindful. If the flow of liquid plastic-type becomes too unsteady, you will discover yourself outside of luck! The particular plastic may take place out with stresses and weaknesses about it. If these kinds of are bad enough, an experienced professional may have in order to throw them out and about! After coming almost all this way!